Our Products

Cold Room & Storage

Industrial Refrigeration

Download Cold Room & Storage Catalogue

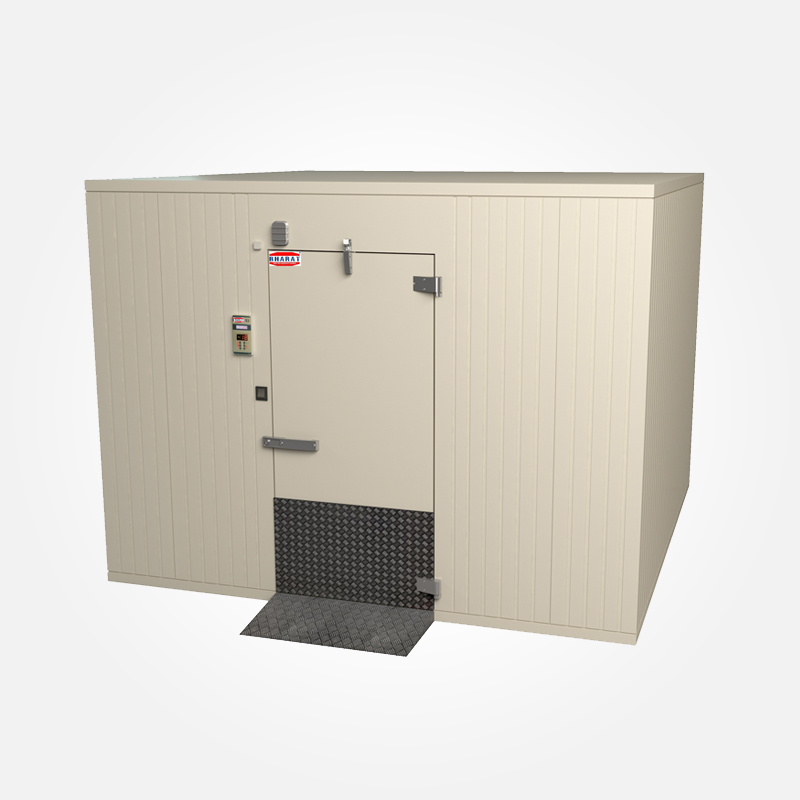

Cold Room

We are one of the trusted manufacturers of Cold Rooms, Walk- in Coolers & Freezers that are specially designed for chilling or freezing applications. The CFC-free refrigeration systems facilitate efficient cooling, freezing of the chamber integrated with user-friendly structure and design. Available in various capacities, these Cold Room are provided with pre-fabricated panels for easy assembly, cam lock in tongue and groove assembly. These Cold Room find wide application in Food Processing, Dairy Products, Fisheries, Hotels-Restaurant, Research laboratories, Chemical and Pharmaceuticals, Ware House Storages, Agriculture, Horticulture-Floriculture etc.

Features

Food safe and CFC free

Wide temperature range and capacity

Pre-fabricated panels for easy assembly, tongue and groove assembly

Micro-processor based electronic control panel board, digital temperature indicator

Energy efficient refrigeration systems attuned to suit high ambient conditions

PUF injected insulation (40kg/m³) , insulation thickness from 60 mm to 150 mm

Safety, high & low temperature alarms & recorders

Auto & manual operation

PUF Panels & Accessories

THICKNESS : 60, 80,100, 125 & 150 mm

SURFACE MATERIAL Gl Pre-Painted Sheet, S.S. Sheet (Grade 304/316 & Surface finish 2B & Mate), Gl PlainSheet, and Plain Galvanized Iron. (Inside & Outside different metal can be placed as per your requirement)

FLOOR :

(A) For Kota stone or concrete floor, PUF Slab with both side tar felt coated.

(B) For Kota Stone or Concrete floor, PUF Panel with Metal Surface at Both Side. Where Panel fits together with cam lock to prevent heat loss.

(C) Aluminium Chequered Plate with Marine Ply.

(D) FRP Cladding on floor

(A) For Kota stone or concrete floor, PUF Slab with both side tar felt coated.

(B) For Kota Stone or Concrete floor, PUF Panel with Metal Surface at Both Side. Where Panel fits together with cam lock to prevent heat loss.

(C) Aluminium Chequered Plate with Marine Ply.

(D) FRP Cladding on floor

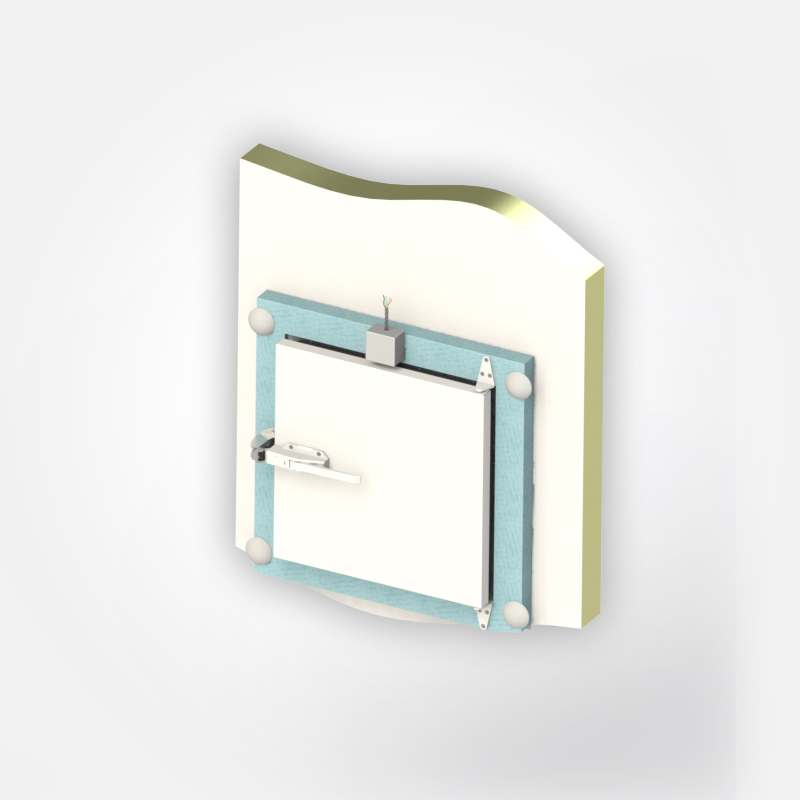

DOOR :

(A)Flush Type Swing Door with FRP Profile, Imported Hardware, Push Type Gasket & replaceable heater for easy door operation & long life Opening Size: 24"x72", 30"x72", 34"x78",46"x84" (Door Opening W X L X H )

(B) Overlap Type Swing door with frame and metal covering by using heavy duty hardware for better strength

Opening Size (WxH): 46"x84", 49"x84", 54"x84",60"x90“ (Door Opening WxH)

(A)Flush Type Swing Door with FRP Profile, Imported Hardware, Push Type Gasket & replaceable heater for easy door operation & long life Opening Size: 24"x72", 30"x72", 34"x78",46"x84" (Door Opening W X L X H )

(B) Overlap Type Swing door with frame and metal covering by using heavy duty hardware for better strength

Opening Size (WxH): 46"x84", 49"x84", 54"x84",60"x90“ (Door Opening WxH)

ROOM SIZE:

(A) Length & Width Minimum 1.78 mt andBigger size 0.146 mt in multiples as perrequirement

(B) Standard Height for 60 mm thickness 2.47mt, 80 mm-2.51 mt, 100 mm-2.55 mt,125 mm-2.60 mt, 150 mm-2.65 mt. SinglePanel Height upto 12 mt and above as peryour requirement.

(A) Length & Width Minimum 1.78 mt andBigger size 0.146 mt in multiples as perrequirement

(B) Standard Height for 60 mm thickness 2.47mt, 80 mm-2.51 mt, 100 mm-2.55 mt,125 mm-2.60 mt, 150 mm-2.65 mt. SinglePanel Height upto 12 mt and above as peryour requirement.

Sliding Door:

Opening Size

Width: 1000/1200/1500/1800 mm

Height: 2100 to 3000 mm

Thickness: 80 mm

Panel Surface Material: Both side GIPPor S.S as per requirement

Opening Size

Width: 1000/1200/1500/1800 mm

Height: 2100 to 3000 mm

Thickness: 80 mm

Panel Surface Material: Both side GIPPor S.S as per requirement

Hatch Window : Opening Size (WxH): 20"x20", 24"x24", 30"x30" Different size hatch window with sturdy frame for easy material movement in high turnoverice cream and dairy industries.

Pressure Ventilator : Tri-action pressure ventilator with/without heater to balance pressure and vacuum inside cold room.

View Port : 12”x12” View port with three layer argon filled,toughen glass which can be visible up to 2°C inside the cold room.

Strip Curtain : Semi-transparent PVC strip curtain for negative temperature application to prevent heat loss and ultimately the power.

| Sr. No. | Parameters | Description |

|---|---|---|

| 1 | Average PUF Density | 40 ± 2 kg/m³ |

| 2 | PUF Blowing Agent | CFC & HCFC Free |

| 3 | Insulation Material | Polyurethane foam |

| 4 | Temperature range | +90°C to -60°C |

| 5 | Panel Type | Discontinuous type with cam lock |

| 6 | M.O.C. Of Cam Locks | Cam locks body material HIPS and male latch is made of nylon Glass field with GI sheet reinforcement. Cam-lock panel joints easy assembly and leakage resistant, panel-to-panel joints. |

| 7 | Type Of Panel Joints | Tongue & Groove Joint with Cam lock and all side rubber gaskets |

| 8 | Corner Panel Available | 12” X 12” X 162”(Maximum Length) |

| 9 | Length of wall & ceiling panel | 2032 mm to 12000 mm 80” to 472.5” inch |

| 10 | Ceiling Suspension items with specs | MS bolt with thermal breaking cap. PVC Round Plate 6 mm thickness x 90 mm diameter Aluminium/MS washer plate for load distribution Anchor bolt (MS) hanging bolt with 40 mm washer 2.0 mm Thickness Sealing to panel MS road Clamp with an insulated crown. |

| 11 | Closed cell content | 90 to 95% |

| 12 | Vapour Permeability | 5.5mg/PASM. |

| 13 | Water Absorption | Less than 2% |

| 14 | Fire Resistance | FR Grade B3 (Fire Retardant Grade) |

| 15 | Compressive Strength at 10% Deformation | 0.21 N/ sq.mm (For PUF only) |

| 16 | Tensile Strength | 0.58 N/ sq.mm (For PUF only) |

| 17 | Adhesive Strength(Foam to Sheet) | 2.9kg/sq.mtr |

| 18 | Dimension Stability | Less than 2% |

| 19 | Panel Facing Availability | With Rib or plain on Demand (Ribs are provided for more strength) |

| 20 | Wall & Celling Panel Facing material | Pre Painted Galvanised sheet, Thickness 0.45mm Plain Galvanised sheet, Thickness 0.45mm S.S. sheet, Grade 316, 0.50mm finish 2B/ 0.6mm mate No.4 S.S sheet, Grade 304, 0.50mm finish 2B/ 0.6mm mate No.4 |

| 21 | Floor Panel Facing Material | PUF Panel with both side tarfelt sheet. PUF Panel with both side 0.45mm GIPP sheet. PUF Panel with outside GIPP sheet, inside 9 mm thick marine ply with 2 mm thick Aluminium Chequered Plate |

| 22 | Specification for Colour Coating | A. A. RAL No. : 9002 or it's nearest

B. Indian Standard code Colour Coating : IS 14246 Galvanizing : IS 277 Base Metal : IS 513 C. Organic Coating : Type RMP (Polyester) D. Zinc Coating : 120 GSM E. Top Primer (Thickness in micron 'μ') : 5 +/- 1 μ F. Top Coat (Thickness in micron 'μ') : 20 +/- 1 μ G. Back Primer (Thickness in micron 'μ') : 4 +/- 1 μ H. Back Coat (Thickness in micron 'μ') : 4 +/- 1 μ I. Guard Film (Thickness in micron 'μ') : 40 +/- 3 μ J. Salt Spray Test /Humidity Test : 750 hrs. /1000 hrs. |

Evaporator Units

Features

Fan - High reliability, lower temperature resistance and low noise external rotor fans.

Coil - High Efficiency heat exchange with in line tube system for minimum loss of air flow between fans and large surface area for better cooling.

Unit Body - Aluminium, PU type Powder Coated, Corrosion resistant and nice appearance body.

Maintenance - Compact, adjustable & easy open able side panels for easy installation.

Condensing Units

Features

High cooling with low power consumption

Designed for high ambient condition up to 55°C

Condensing coil with inner grooved copper tubes & aluminium fins

Efficient fans with external motors for single phase and three phase

High & low pressure cut-out including mounting brackets, wired to terminal strip

Large size filter drier, moisture indicator, solenoid valve, oil separator and accumulator

Shell & tube type condenser with high cooling and capacity for high ambient conditions